Arc Welder Download Macbook Air

High efficiency electronic inverter power supply Clean-cut infinitely adjustable output power Professional grade duty-cycle performance Microprocessor control with LED.

Our site uses cookies to improve your browsing experience and to strengthen the services of the website. Cookies are not required for all aspects of service, but some of our services may not function properly if you choose to disable cookies. When your device allows it, we use these cookies to better understand how you interact with our services, to monitor usage patterns, personalize featured content, and remembering your language selection.

- Researchers from the University of Illinois Urbana-Champaign have developed a brain-computer interface system that makes it possible for a person to control a welding robot using only their thoughts.

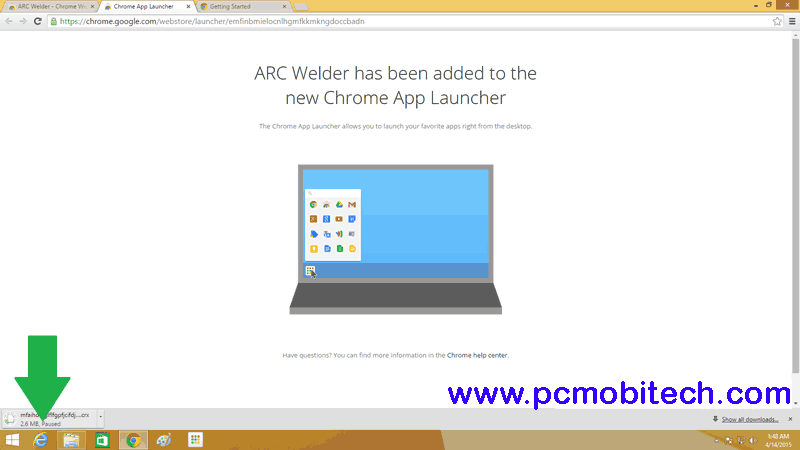

- Download ARC Welder, and open it using Chrome's App Launcher. Once ARC Welder is up an running, it'll ask you to select the APK for the Play Store app that you need to run on your computer.

We want to be transparent about the data we collect and how it is used, so you can exercise control over your personal data. For additional information, please refer to our Cookie Policy.

Arc Welder Chromebook Download

Cookies used by this site

- - Cross-device tracking

- - Browser history

- - Google Tag Manager

- - Google Adwords

- - HasOffers

- - Ad Partners

Perfect World International, the visually stunning free-to-play online game with unparalleled character customization and amazing gameplay.

You are leaving ArcGames.com

Heads up, you are now leaving Arc Games! Remember to not share ac- count information as the site you are attempting to reach is not affiliated with Arc Games.

Okay - I UnderstandContinue to link and leave Arc Games.

No thanksTake me back to Arc Games.

Marketplace Update

November Marketplace Update The following sales & discounts are available:Start: 11/25/2020 1:00AM PT (10:00 CET)End: 1/6/2021 1:00AM PT (10:00 CET) Silent EpiphanyX1 – 25 Silver...

Login Rewards

Login RewardsLogin Event Starts: Tuesday, November 24th @ 10:00 AM PT (19:00 CET)Login Event Ends: Sunday, January 3rd @ 11:59PM PT (Monday, January 4th at 08:59 CET) If you are LV80+, ea...

Spend Rewards

For a limited time, spend Gold at the Boutique and earn great rewards! Start: November 20, 2020 @ 9:00 AM PT (18:00 CET)End: December 4, 2020 @ 11:59 PM PT (December 5 @ 08:59 CET) ...

More News

Overview

Platform:

Genres:MMO, Customization, PvP

Developer:Perfect World Entertainment

Publisher:Perfect World Entertainment

Release Date:Sep 02, 2008

File Size:16GB

System Requirements

To ensure a smooth gaming experience, we recommend that you meet the following settings:

Windows

| Operating System | Windows 7, Windows 8.1, Windows 10 |

| CPU Intel® Pentium® 4 at 1GHz, (Mid to High Range Dual-Core 2.5GHz CPU or better recommended.) | Intel® Pentium® 4 at 1GHz, (Mid to High Range Dual-Core 2.5GHz CPU or better recommended.) |

| RAM 1 GB of RAM (2 GB or more recommended for XP, 3GB or more for Windows Vista and Windows 7) | 1 GB of RAM (2 GB or more recommended for XP, 3GB or more for Windows Vista and Windows 7) |

| Hard Disk | 13.4 GB Free HD Space |

| Graphic Display 3D video chipset with pixel and vertex shader model 1.3 supported. GeForce 4 Ti4200 64MB or ATI Radeon 8500 64MB or newer for Windows XP. For Windows Vista and 7, a GeForce FX 5200 128MB or ATI Radeon 9500 128MB or newer is needed. | 3D video chipset with pixel and vertex shader model 1.3 supported. GeForce 4 Ti4200 64MB or ATI Radeon 8500 64MB or newer for Windows XP. For Windows Vista and 7, a GeForce FX 5200 128MB or ATI Radeon 9500 128MB or newer is needed. |

| Sound Drivers | DirectX 9.0c compatible sound card |

| Network Broadband Internet connection | Broadband Internet connection |

Game Info

PWI is a stunning free-to-play MMORPG where inhabitants of the pristine Perfect World must unite to battle against the Wraith - undead creatures who seek to destroy all of creation. Amidst a realm of stunningly rich environments, players can fly freely through the skies, explore dangerous dungeons, or join intense PvP battles for power and land.

Cross Server PvP

|

Free-form Flying

|

Constantly Evolving World

|

Create the Perfect Character

|

Fantasy Violence, Suggestive Themes

© 2017 Perfect World Entertainment Inc. All rights reserved. Published by Perfect World Entertainment.

Marketplace Update

November Marketplace Update The following sales & discounts are available:Start: 11/25/2020 1:00AM PT (10:00 CET)End: 1/6/2021 1:00AM PT (10:00 CET) Silent EpiphanyX1 – 25 Silver...

Login Rewards

Login RewardsLogin Event Starts: Tuesday, November 24th @ 10:00 AM PT (19:00 CET)Login Event Ends: Sunday, January 3rd @ 11:59PM PT (Monday, January 4th at 08:59 CET) If you are LV80+, ea...

Spend Rewards

For a limited time, spend Gold at the Boutique and earn great rewards! Start: November 20, 2020 @ 9:00 AM PT (18:00 CET)End: December 4, 2020 @ 11:59 PM PT (December 5 @ 08:59 CET) ...

More News

Overview

Platform:

Genres:MMO, Customization, PvP

Developer:Perfect World Entertainment

Publisher:Perfect World Entertainment

Release Date:Sep 02, 2008

File Size:16GB

System Requirements

To ensure a smooth gaming experience, we recommend that you meet the following settings:

Windows

| Operating System | Windows 7, Windows 8.1, Windows 10 |

| CPU Intel® Pentium® 4 at 1GHz, (Mid to High Range Dual-Core 2.5GHz CPU or better recommended.) | Intel® Pentium® 4 at 1GHz, (Mid to High Range Dual-Core 2.5GHz CPU or better recommended.) |

| RAM 1 GB of RAM (2 GB or more recommended for XP, 3GB or more for Windows Vista and Windows 7) | 1 GB of RAM (2 GB or more recommended for XP, 3GB or more for Windows Vista and Windows 7) |

| Hard Disk | 13.4 GB Free HD Space |

| Graphic Display 3D video chipset with pixel and vertex shader model 1.3 supported. GeForce 4 Ti4200 64MB or ATI Radeon 8500 64MB or newer for Windows XP. For Windows Vista and 7, a GeForce FX 5200 128MB or ATI Radeon 9500 128MB or newer is needed. | 3D video chipset with pixel and vertex shader model 1.3 supported. GeForce 4 Ti4200 64MB or ATI Radeon 8500 64MB or newer for Windows XP. For Windows Vista and 7, a GeForce FX 5200 128MB or ATI Radeon 9500 128MB or newer is needed. |

| Sound Drivers | DirectX 9.0c compatible sound card |

| Network Broadband Internet connection | Broadband Internet connection |

In modern life, advance technology attaches to us everywhere. Among the technology, a MIG welder is an essential tool. What is a Mig welder, and why you need this? A Mig welder helps your devices making the job more straightforward. To develop home tools like furniture or construction sites, need several tools to prepare for design and build a well living condition. In this condition, a Mig helps to make or resize tools in a quick moment. Where it used most? Most of the construction sites, furniture develop mills, and tools developer well renown about Mig. By its using sides, they face some mig welding troubleshooting issues. In this troubleshooting issues, have some common problems and solution. The expert well recognized the common issues and resolution. Like a beginner, they can’t suitably find out the issues. Let’s see the matter according to experts views:

Machinery Issues

Cause: There are several features and types of Mig in this century. Some uses for tools are shaping and some applications to develop new tools. In the examples of the machine, they may not start or become hang for many reasons. The reason are :

-Power Supply Problem

-Power Cod or wire burned

-Internal coil, fuse, and circuit get jammed and dead

-Get water wet – so that causes electric function may burn

-Overloading power voltage

Solution:First, all of to make sure your machine performance, its switch getting works or not. If the switch is okay then plugs and rest function will work correctly, to get swift action, use digital Mig that helps you to monitor self the power supply and your machine overall loading performance. If you want to work for several hours a day, then don’t run your machine for a long time. Give rest self and your device after running 20 minutes at once shift. Then start after 10 minutes break and find your machine as newer as like the first touch.

Welding machine doesn’t shut down

Cause: If you switch off your device and the Mig welder doesn’t go off until you cut off the power supply, it means merely your liner needs to switch out.

Solution: By switching liner and connection, it helps to replace things, worn and get back your job in quick time.

Welder become defected :If you notice your welder get jammed or not turn on, it means that some parts of the MIG itself need to malfunction. These parts need to take some actions and repaired. Below are some common welding defects discuss with solutions.

Cause: A widespread welding defect may be as a result of improper wire feeding, which is caused by a worn-out the drive roller from a welder.

Solution: Periodically remove the drive rolls to clean up your welder to use it next time as fresh. Use a wire brush to remove the dirt on the liner. By doing this, it removes pressure and helps to hold in hand smoothly and operate. Also, inspect the drive rolls time to time for wear, and replace if it is worn-out.

Cause : Small welding defects occur when the tip of the welding gun is worn-out. When this happens, the solder will not process correctly.

Solutions: Replace the tip from the welding gun immediately.

Cause : Permeability may occur on the surface as a result of inadequate gas flow or bad wiring. It is a prevalent welding defect. There is another reason is, gas permeability factor it arises due to Inconsistent gas shield. It also happens by over lead to constant problems. Permeability occurs when the shielding gas altered and air contaminates the weld puddle. We suggest, use shielding gas to protect the weld puddle from the wind. At the same time, it works as a stabilizer.

Solutions: Check every use before the gas line and clear out the obstruction. Also, the gas shield needs to be plugged correctly to avoid leakage. Ensure first, your wire connections stay appropriately. First of all, check the gas hose with the tools and remove hose contamination. If the link set correct, there will be no loss of a gas shield. It helps to secure the body and environment. So, check the appropriate amount of shielding gas stated in the Mig; for this, you can follow the user manual to ensure your best handling.

Cause : Metal is a tool which used for many purposes like made hardware tools, furniture likes bed, almirahs, building construction sites, etc. purposes. To use Mig on metal, a welder needs high voltage electric power supply as well as its functional power to cut in a simple touch. It doesn’t so, a machine can damage sooner.

Solution: So from the facts sides, the solution is to advise you, don’t give to pressure on the metal side either on the device, both may disrupt your job and reason for the machine.

MIG Welder Wire or Cod Internal and External Functional Issues

Cause: Check out your machine wire, voltage performance, and overall machine sides before every work.

Solution: Drive rolls tend to wear out eventually, and so they need regular replacement. Also, I need to check the grooves on the rolls for any visual indications of wear.

Cause : Bird nesting is a big issue for welder function. It involves tangled wire, which leads to halting the wire feed.

Solution : To avoid the problems, you need to Flip up the drive roll and pull the wire out first. Make tangled trim wire and re-thread from back part. Also, make sure that it does not stay at higher. By this method, your nest and welder both become fresher.

Arc Welder Download Macbook Air 13.3

Cause : The backside of welder may burn by overloading voltage. Another cause of cooking, if the welder built-in hardware, they cause of burn by running.

Solution: By using plodding wire feed speed with a gun, it helps to close the base metal, which leads to wire melting and fusing with the contact tip. Then replacing the damaged contact tips and increase the wire feed speed to make sure that you maintain an appropriate distance between your gun and work piece. Let's startup with a new mood!

Cause: It can be liner blockages, the use of a wrong-sized ship or improperly trimmed coatings.

Solution: The gun liner must shape according to the way to use the wire fed through. In case of a blockage, need to check and clean or replace the liner. Also, check the manufacturer’s directions before receive your order.

Cause : Check copper strands that located inside the gun. It helps to work fine. So use manual and check the break and wear out with same time — the results come faulty by wire and electric power supply.

Solution : During use, if you notice that a particular area is getting very hot, it’s a clear indication of internal gun damage. To prevent the issues, immediately replace the firearm.

Cause: If the electrode holder gets overheated, there might be a loose connection or an inappropriate duty cycle. So, replace the electric line.

Solution: Tighten the loose connections, in the case it faulty plugs or inappropriate duty cycle occurs. Then the electric holder needs to change.

- Problem #7. Electrical shocks Occur while touching the welder

Cause : Electrical shocks on welder may occur if the frame of the welding machine is not grounded correctly.

Solution: In the case of electrical shocks, you must follow all the instructions with the user manual first. Also looks welder frame how it attaches on the ground. The framework of welder needs to ground correctly, that prevent you from electrical shocks.

Cause: If the welding cable gets heated fast, it results in incorrect cable size or duty-cycle.

Solution : Replace the cable and follow the user manual.

Cause : The welder cables might damage by over-usage.

Solution: By notice any sign of damage in the cable, you have to change cable as soon as possible. It is so advised to replace damaged wire quick to get quality time work.

Cause: During running the welder, shrinkage cracks on your weld may occur. It happens by the bead may be too small and concave, or the wire gets rusty. By insufficient heat from inputs, may lead to weld bead. If the dot appears to be ropy or convex, it is an indication that the setting needs to use too cold for the width or thickness of the welded material.

Solution: First, determine the amperage disrupt. It is ideal for the thickness of the material that you want to weld. If the amperage gets higher, check the voltage. It may be that the energy is too low, and this may lead to other problems — an excellent way to test if the tension set correctly by listening to the arc sound. You find cracking sound, steady hiss, or a loud noise are by the result of high amperage, high voltage or low voltage. Arc average amperage and tension, the arc should have a steady buzz. Make sure the beads are adequate in size. Clean the wire before every weld in the right way. It helps to work in better form and keep you safe.

Cause : If you notice oblique cracks on your weld, it may be due to fast welding speeds by the high voltage of arc.

Solution: Lateral cracks avoided by maintaining a steady welding speed and avoid over speeding running. The electric flow and arc voltage need to stay and run in constant tension.

Cause :Excess spatter is a widespread welding defect and caused by either excess CO2, high voltage, or as a result of inappropriate impedance. The weld puddle can melt the metal and leave the spatter along with the bead. It may disrupt the weld appearance and lower the strength by damage fusion.

Soluation: Excess CO2 can be the reason for overheating up using a gas heater. Excess spatter can also avoid by applying the correct voltage. Essential to use accurate contact tips and nozzles, as it can lead to an erratic arc and result in excessive spatter.

Cause: Using a forehand technique often in a flatter bead shape.

Solution: for this often, the ideal technique is to use an angle between 5-10 degrees.

Use Cold Lapping Short-Arc Transfer Process: Lack of fusion occurs by cold lapping through the short arc transfer process. In this process, the wire should touch the weld pool in the right forms. The end of the wire get melts and detaches by short circuit system. Fusion happens due to the metal weld pool melts.

Solution : First, set the amperage and voltage power correctly. If the problem persists, though, you may need to change the welding technique. The spray-arc transfer method highly recommended.

Conclusion

In summary to say, until you cover a sound knowledge of Mig Welding Troubleshooting steps can clear and help you to handle the machine properly. By following the guideline, it allows welders to correct use technique and stay away from disrupting things to complete job smoothly and smartly.